Introduction

Advanced modular operation theaters (MOTs) are now a crucial component for the best hospital infrastructure services provider, as the way procedures are performed has changed significantly in recent years. Traditional operating rooms are unchanging and unadaptable. They frequently have trouble adhering to ventilation requirements, technology integration, and infection control measures that are always evolving. In contrast, MOTs are constructed with prefabricated panels composed of non-porous materials coated with antimicrobials to reduce microbial load and particle shedding. These structures adhere to international standards like ASHRAE 170, HTM 03-01, and NABH. Laminar airflow, HEPA filtration, and hourly controlled air changes are how they guarantee air purity. By lowering the risk of surgical site infections (SSIs) and facilitating consistent performance across specialties, a precise design improves surgical safety.

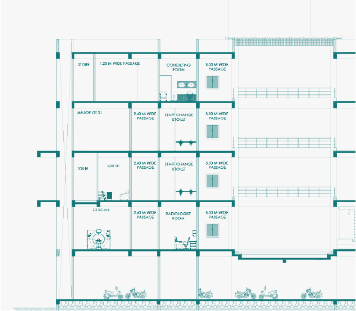

Modular Operation Theatres are Scalable and Rapidly Deployable Surgical Solutions

One of the main advantages of modular operating theaters (MOTs) is their rapid scalability and quick installation. MOTs are constructed using prefabricated panels that may be assembled in a matter of weeks, in contrast to traditional construction, which can cause hospital operations to be delayed for months. When hospitals are faced with lengthy surgical waiting lists or need to increase surgical capacity during emergencies, like a pandemic, this speed becomes crucial.

Flexibility is also another significant benefit. To install new imaging systems, hybrid surgical setups, or upgraded HVAC units without having to close the theater for extended periods of time, the wall panels can be moved or removed. Additionally, advanced MOTs are built for digital integration, allowing for smooth connections with PACS, hospital electronic medical records, and surgical navigation systems. This makes them ready for next-generation procedures like robotic-assisted surgeries. By combining fast deployment, easy upgradability, and digital compatibility, MOTs help hospitals balance precision in surgery with smooth operations, ensuring that infrastructure keeps up with evolving clinical needs. Using the best medical equipment and products in MOTs helps doctors work faster, safer, and gives better results for patients.

Infection Control in Modular Operation Theatres

Infection control is one of the biggest challenges in surgery, and also the most important. Modular operation theatres (MOTs) are designed to tackle this by building safety right into their structure. They use HEPA filters along with laminar airflow systems to supply a steady flow of ultra-clean air, while positive pressure keeps contaminated air from entering the sterile zones. This creates a protected surgical space where germs are kept to a minimum.

To maintain this safe environment, MOTs deliver 20–25 air changes every hour, meeting strict NABH and ASHRAE 170 guidelines. This setup greatly reduces the chances of surgical site infections (SSIs) and ensures patients, especially those who might be undergoing high-risk or complex surgeries, are better protected. By combining advanced engineering with clinical needs, MOTs turn infection control from a challenge into a built-in advantage.

The structural elements of MOTs further reinforce asepsis. Antibacterial wall cladding reduces surface bioburden, hermetically sealed doors prevent uncontrolled air exchange, and antistatic flooring limits particle accumulation during movement. These architectural and microbiological safeguards operate in synergy, lowering postoperative complication rates and improving recovery timelines. By translating precision engineering into measurable clinical outcomes, MOTs exemplify how infrastructure can directly shape surgical success.

Higher Efficiency with Technological Integration

Modular operation theatres (MOTs) are built to support smooth functioning of advanced surgical technologies and enable clinicians to work with higher precision and efficiency. Modular operation theatres (MOTs) are built to support the latest surgical technologies. They can easily accommodate robotic-assisted systems, advanced imaging during surgery, and hybrid workflows where diagnosis and treatment happen in the same space. Surgeons benefit from high-definition visualization tools connected to PACS and navigation systems, giving them real-time data that improves decision-making and boosts confidence during complex procedures. Environmental panels built into the theatre walls allow precise control of temperature, humidity, and airflow with just a touch, ensuring the surgical team always works in the best possible conditions.

These theatres also make remote collaboration and training possible. Using ultra-HD cameras and secure connections, surgeries can be live streamed for expert input from anywhere in the world. This is especially valuable in demanding specialties like neurosurgery and cardiac surgery, where even the smallest margin of error matters. With digital integration, surgeons receive real-time guidance that can directly influence outcomes and improve patient safety. This convergence of infrastructure, robotics, and imaging systems marks a transformative shift in surgical practice, redefining both procedural accuracy and patient safety.

Are MOTs Cost-Effective?

Initially, modular operation theatres (MOTs) may look more expensive than regular operating rooms, but their long-term savings are significant. The prefabricated wall and ceiling panels are built for a long life, and need fewer repairs or refurbishments compared to traditional structures. Energy-efficient HVAC systems, LED surgical lights, and smart environmental controls also help cut down ongoing utility costs. Since MOTs are designed to meet international standards like HTM 03-01 and ASHRAE 170, hospitals not only ensure patient safety and accreditation but also avoid heavy penalties that can come with non-compliance.

Another big reason why MOTs are cost-effective is that they can be built and scaled at a fast rate. They can be set up in just a few weeks instead of several months, because of which hospitals can start surgeries sooner and start getting returns on whatever they have invested. A modular design means hospitals can expand or upgrade their technologies without major changes. Some hospitals have tight budgets and even the space is limited. In such cases, MOTs offer affordability, flexibility, and high-quality surgical environments.

Infra.Health’s Contribution in Providing Emergency-Ready and Future-Focused MOTs

Infra.Health’s modular theatres have shown their value in emergencies and remote locations. During the COVID-19 crisis, we delivered modular surgical units that expanded hospital capacity while fully meeting NABH and WHO standards. In regions lacking medical facilities, our prefabricated units have brought safe surgical care to areas where permanent hospitals are not yet possible. The future healthcare is now progressing toward robotic surgeries, AI-driven support, and eco-friendly design. Infra.Health’s modular operating theatres stand out as both an immediate solution and a future-ready platform for surgical excellence.

Key Features of Infra.Health’s Advanced Modular Operation Theatres

- Seamless antibacterial wall and ceiling panels for infection control

- Hermetically sealed automatic doors enhancing sterile environment

- Laminar airflow system with advanced HEPA filtration technology

- Antistatic and easy-to-clean flooring for hygiene maintenance

- Integrated surgical lights and ergonomic pendant systems

- Energy-efficient HVAC zoning for optimized climate control

- Compatibility with robotic-assisted and minimally invasive surgeries

- Real-time digital imaging and AR navigation integration

- Prefabricated panel systems enabling rapid, seismic-resistant installation

- Centralized digital dashboards for scheduling, compliance and control